Looking for a 100% quality and affordable source for your next project?

We develop your application in a step by step process.

Our engineering team will help develop a solution for a user’s application. We will recommend products, systems, and help with granite design to suite a wide range of applications. From small projects to big developments.

Read More

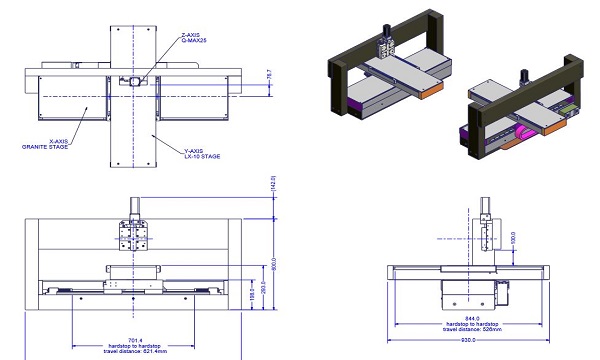

When requesting a custom system, request a simple drawing is prepared with your quote to demonstrate the final product. Along with a detailed description of all parameters of your design, NUTEC will engineer a solution to any application.

Read More

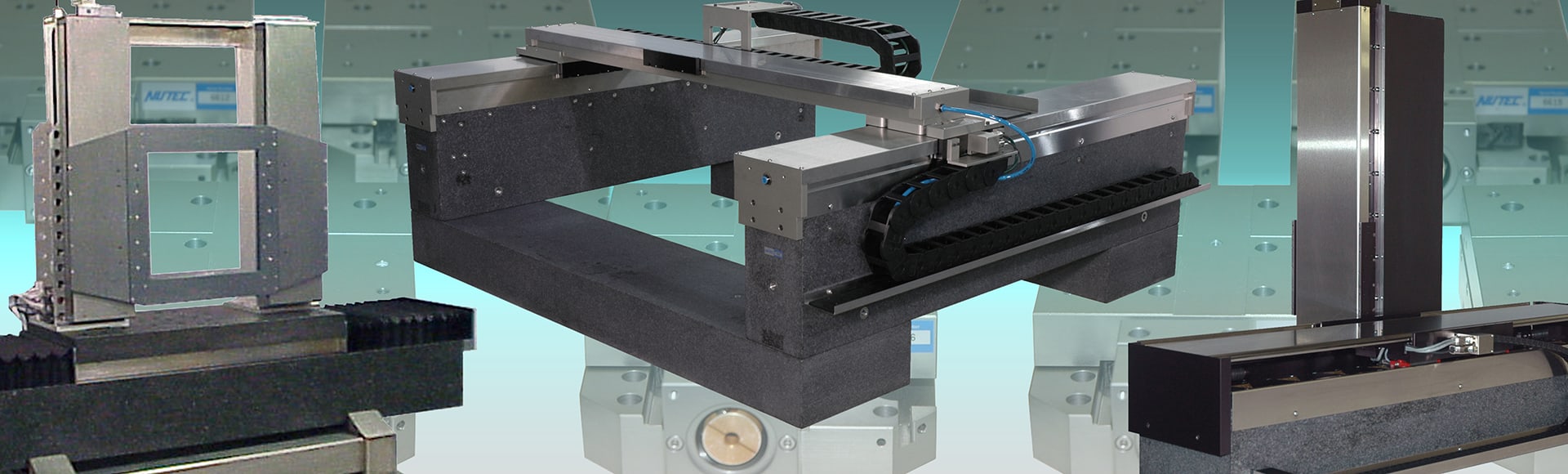

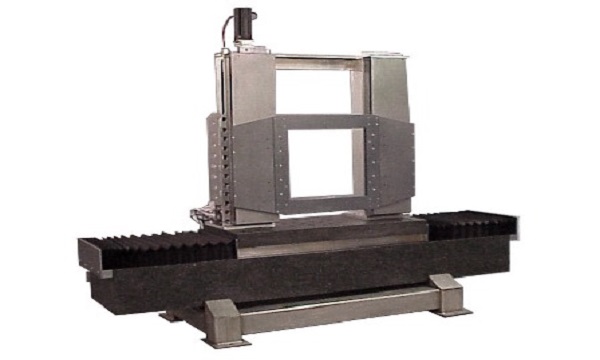

NUTEC Engineers integrate current products into multi-axis positioning systems. With the use of our MICROMATIC 9 controller, be able to seamlessly control up to 8 axis of motion.

Read More

NUTEC has engineered positioning platforms by integrating our products with a custom platform design. Our engineers have produced platforms such as our CMS, MMC tube cutters and FGS flat bed cutting platform.

Read More

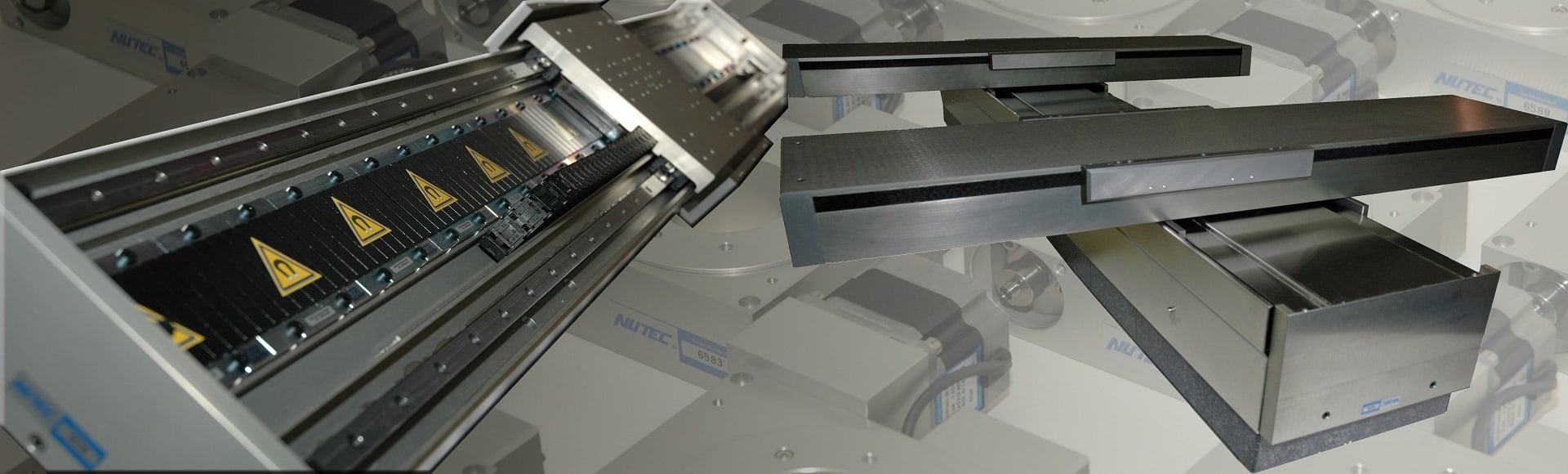

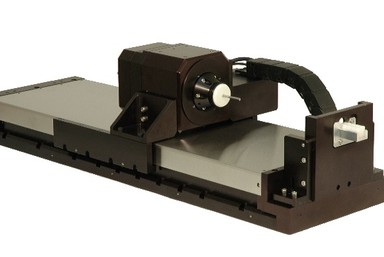

linear motor stage systems are built for acceleration and high speed. These stages lack the inertia and mechanical gearing advantages of traditional; screw drive stage and therefore more application specific.

Custom-built ball screw drives reduce lead error utilizing a high preloaded duplex and angular thrust bearing. The drive motor connection is facilitated through a custom-built mono-block coupling with high torsional stiffness.

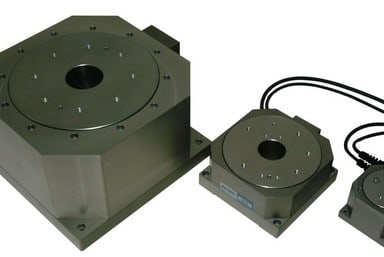

Rotary positioning stage by NUTEC provide bolt-on solutions for ant applications where precision rotary positioning or indexing is required. Three varieties of systems are available in sizes to fit most applications.

Our feature packed XY table products cover a range of positioning requirements, from robust industrial grade screw drive positioning tables to nanometer resolution metrology products.

Precision Systems for OEM and specialty positioning applications.

Low profile rotary, high speed, perfect for tube cutting. Linear and rotary stage with pneumatic module for collet adapter and front gripper

Multi-axis

Lineax-8A linear Motor driven stage suitable for applications where reliable 24/7 operation, precision positioning and ease of use are required.

Linear Motor Stages

flexdrive-4 A Precision Ball Screw driven Stage suitable for all orientation applications, precision positioning, and ease of use required.

Screw Driven Stages

T-Max™ series of precision, direct-drive rotary servo positioning stages are ideal for today’s high performance technology environment.

Rotary Stages

NUTEC was acknowledged by the following.

NIF Project of the Year Award 2010

Lawrence Livermore National Laboratories

NUTEC provides products that excel in many fields of application.

NUTECs ability to produce high precision machines allows for the best production of medical equipment. From the production of stents to lab testing and research, our systems and stages excel in performance and reliability.

Read More

From wafer inspection to processing, NUTEC stages deliver the highest quality and performance. Cleanroom and vacuum systems are available standard or for custom design.

Read More

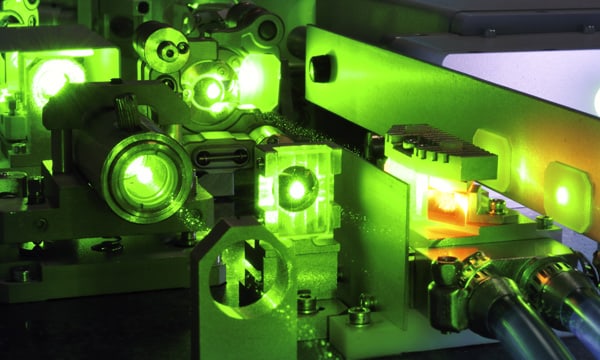

From singular linear or rotary stages to complete multi axis systems NUTEC offers years of engineering experience to improve optical fabricators processes.

Read More

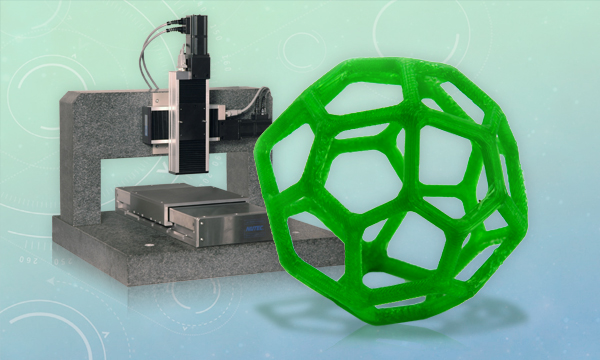

NUTEC stages can stack and be orientated for any additive manufacturing configuration. High speed servomotors and high-resolution encoders allow for precision and speed when preforming additive manufacturing.

Read MoreNUTEC Mechatronic Systems' positioning is based on perfection. Engineering and design are focused on details and balanced design, flawless fabrication and precision machining to exacting standards and consistent quality.

Nutec ComponentsCall us or email us for formal quotations. We can be reached during the week at these times.

Fill out the form below and we'll get back to you.