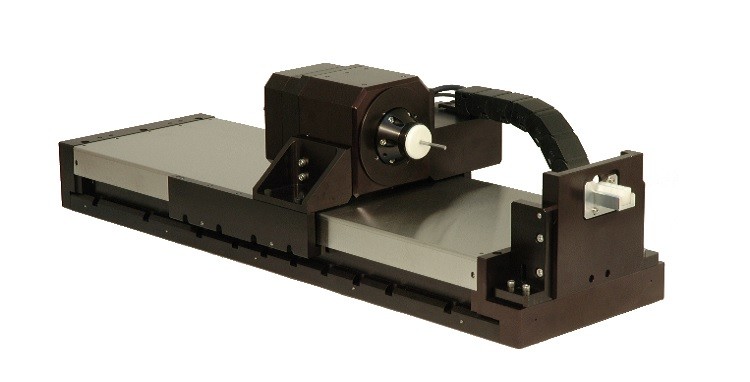

Laserlathe is a completely integrated motion platform system for automated production in cylindrical laser cutting operation.

The LaserLathe advanced technology design creates a linear-rotary motion sub-system which expands the performance envelope for speed, precision and user friendliness. Typically, these attributes are highly desirable on laser machining systems for tube cutting operations, micro-drilling, helix/spiral cutting, surgical instrument production, implant machining, micro-welding and similar operations requiring highly precise and coordinated multi-axis linear-rotary motion.

Specific characteristics are these capabilities:

Simple design with minimal number of parts: easy end-user operation and lower cost of ownership. The end user benefits from expanded reliability and less down-time.

See The Brochure for more purchasing options.

Designed for tube cutting and implant manufacturing, the LaserLathe can also be applied to wide ranging production system applications where small diameter components require precision machined features such as spiral/helix cutting, micro hole drilling, scribing, cutting and micro-welding. Applications would include components for microwave and antennae systems, medical syringes, surgical wires, fuel injectors, ink jet nozzles and other small diameter, tubular manipulation applications requiring a combination of high volume, precision and meticulous quality.

LaserLathe is an advanced technology tool, built to satisfy demanding requirements in high precision laser material processing applications. LaserLathe is ideally matched to the medical stent production process and adaptable to other laser manufacturing processes involving linear and simultaneous rotary motions. Addressing sequential points of interest on the circumference of round work pieces, tubing or bar stock similar to a CNC Lathe. Conceptualized and designed for this purpose, it offers high productivity, ease of operation and superb precision operation in a versatile and ready to integrate package.

| Specifications | Linear Axis | Rotary Axis |

|---|---|---|

| Travel | 250 mm - 625 mm | ± 360º continuous |

| Accuracy | 3 µm ± 2.5 µm/125 mm LIBEC*: ≤ 1 µm |

≤ 25 arc second |

| Repeatability | ± 1 µm | ± 4 arc second |

| Straightness | ± 1 µm / 100 mm | N/A |

| Flatness | ± 1.5 µm / 100 mm | N/A |

| Yaw | ≤ 15 arc second | N/A |

| Pitch | ≤ 15 arc second | N/A |

| Maximum Speed | Max: 1000 mm/sec Cutting Speed: 40 mm/sec |

Max: 100 rad/sec Cutting Speed: 15 rad/sec |

| Maximum Force (Continuous) | 150 N | N/A |

| Maximum Torque (Continuous) | N/A | 4.9 Nm |

| Resolution | 50 nm | 1.095 arc second |

| TIR Inside Collet Adapter | N/A | ≤ 2 µm |

| Rotational Inertia | N/A | 0.001 kg·m² |