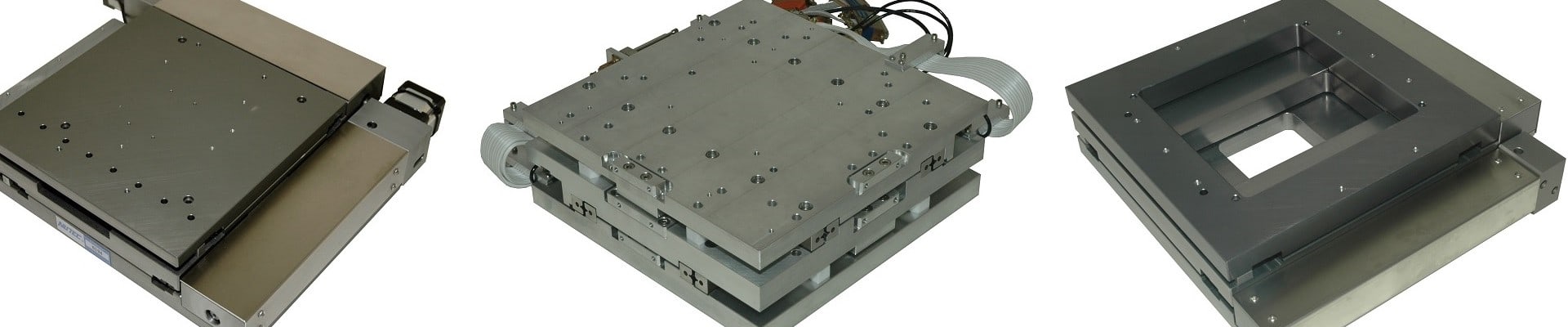

METROSTAGE Linear X-Y table series are high precision stages designed as an integral X/Y compound table for precise positioning. METROSTAGE is available with either solid top or in an open frame configuration.

This stage structure is a three-piece construction, which has been designed for minimum distortion and highest precision stage geometry. Stiffness and stability have been maximized to achieve the highest support and integrity. The backlash-free pre-loaded guide system achieves smooth, low-friction, precision motion for highly accurate positioning and trouble free long-term performance.

The METROSTAGE Series has a very wide range of application, because of adaptable and configurations and execution, offering many different motion platforms with different characteristics. Many applications are found in the metrology and fabrication fields, where a precise, compact X/Y motion platform is desirable. Other typical applications are found in semiconductor assembly, testing, and fabrication areas, video inspection, micro-machining, laser machining, high-speed fabrication, laser and inspection work. Many customers utilize the stage with manual turn knobs, because of the insufficient precision performance of conventional microscope stages.

· Travels from 100mm x 100mm to 300 mm x 300mm

· Stage height as low as 60 mm

· Open Frame or Solid Top

· Clean Room Compatible

· Vacuum Compatible

· Non-Magnetic

· Cross Roller

· Quad-Vee Lock Needle

· Hybrid Guide Bearings

· Precision ground ball screw

· Linear Motor iron core/ironless

· Ceramic Servo Motor

· Rotary Encoders

· Linear Encoders

· Laser Scale Encoders

| MS-100 ST | MS150-ST | MS200-ST | MS300-ST | ||

|---|---|---|---|---|---|

| Travel Length (mm) | 100x100 | 150x150 | 200x200 | 300x300 | |

| Trajectory Control | |||||

| Accuracy | |||||

| Standard Precision SP | ± 7.5µm | ± 10µm | ± 15µm | ± 20µm | |

| High Precision HP | ± 5µm | ± 7.5µm | ± 10µm | n/a | |

| Extra High Precision XHP | ± 3µm | ± 4µm | ± 6µm | n/a | |

| Straightness/Flatness | |||||

| Standard SP | ± 8 µm | ± 10 µm | ± 12 µm | ± 20 µm | |

| High Precision HP | ± 3µm | ± 4 µm | ± 6 µm | n/a | |

| Extra High Precision XHP | ± 3µm | ± 4 µm | ± 5 µm | n/a | |

| Yaw/Pitch/Roll | |||||

| Standard SP | 20 arc-sec | 20 arc-sec | 20 arc-sec | 20 arc-sec | |

| High Precision HP | 10 arc-sec | 10 arc-sec | 10 arc-sec | n/a | |

| 2 axis system all | |||||

| Orthogonality | |||||

| Standard SP | 10 arc-sec | 10 arc-sec | 10 arc-sec | 10 arc-sec | |

| High Precision HP | 5 arc-sec | 5 arc-sec | 5 arc-sec | n/a | |

| Extra High Precision XHP | 3 arc-sec | 3 arc-sec | 3 arc-sec | n/a |

| MS-SP | ||

|---|---|---|

| Drive System | Step motor, Servo motor, Linear Servo Motor, Ceramic Servo Motor | |

| Maximum Acceleration | Payload Dependent | |

| Maximum Speed | Linear Motor Drive 400 mm/s Ball Screw 200 mm/s | |

| Maximum Peak Force | To match application: MS200 Linear Motor 72N, MS250 Linear Motor 108N | |

| Maximum Continuous Force | To match application: MS200 Linear Motor 20N, MS250 Linear Motor 25N | |

| Recommended Maximum Load | ||

| L1 Parallel to base | 15 kg | |

| L2 Tension | 15 kg Perpendicular to base | |

| L3 Compression | 15 kg Perpendicular to base | |

| Feedback | Non-Contact LinearEncoder System | |

| Sinusoidal Output | 1V(P-P) 20 micrometers/cycle 4096x interpolation | |

| TTL resolution | 50nm | |

| Repeatability | ≤1µm | |

| Construction | Aluminum Alloy Body Hard Coat Anodize |