NUTEC Starts by helping our customers determine the right system for their application. Our dedicated team of engineers will determine the correct products depending on one application.

Some examples of applications are listed below!

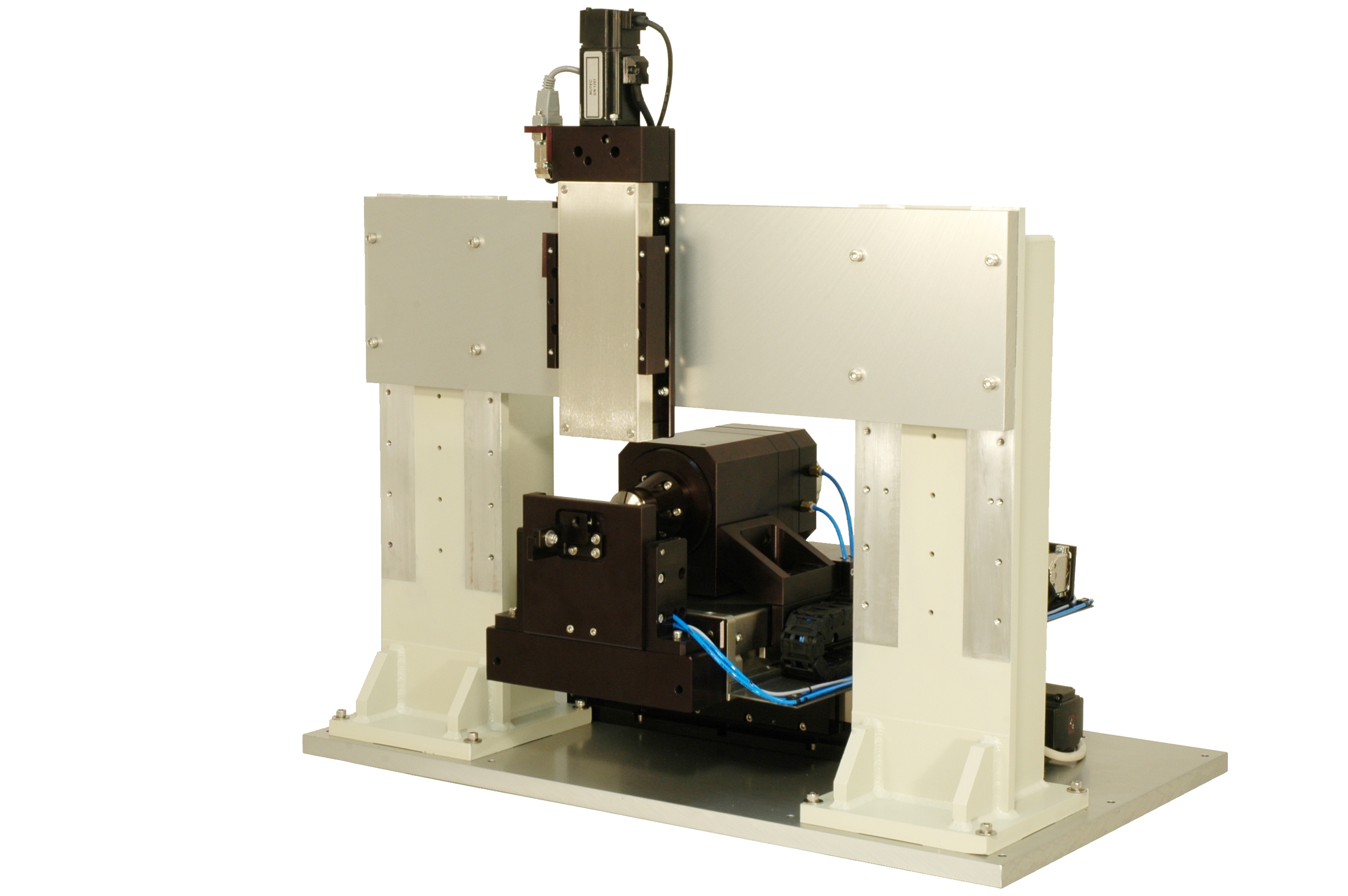

Introducing the Femto Laser Motion System. The linear-rotary axis platform LaserLathe is mounted on a Transverse Axis to execute off-center axis cuts under the fixed femto laser beam.

This architecture also allows for controlled motion U-Axis cross cuts with programmable velocities and acceleration-deceleration rates.

The motorized Z-Axis is also programmable and has sufficient payload capacity to carry extensive hard optics for beam delivery. The vertical axis is mounted on a fixed bridge with provisions for hard optics mounting.

The entire motion subsystem is controlled from a NUTEC MICROMATIC-9 4-Axis Digital Servo Control. With the PCNC system the operator interface is easy and convenient with a Windows™ based Graphic User Interface nuFace serving as an HMI. This GUI is G&M-Code enables to facilitate programming in RS-274 Universal programming language.

Touchscreen enabled display monitor makes it easy for the engineer or operator to interface and control, monitor and command the system. Manual jog controls and soft keyboard allow full command directly a the system.

Workpiece capacities range from 0,2mm to 13mm diameter [ .008″ to .50″ ] and 250mm [10″ ] travel length to 625mm [24″ ]

Precision Micromachining with Nutec. Each type of application has a set of parameters that are critical to the successful implementation of the process. The following are most common to most systems

One of the fundamental aspects of a positioning system is the level of precision that is required. Since the significant cost driver is the level of accuracy, a system should be carefully evaluated and specified for the positioning performance required at the point of interest. These are the first parameters that need to be addressed:

Once these have been established, NUTEC will analyze and select the most advantageous architecture, translator and control product to achieve the given application parameters. The necessary drive and guide technology will be selected, the position encoding concept decided, control capabilities selected and customer’s preferences considered.

A critical capability in modern micro-machining applications is the ability of a system to

NUTEC specializes for many years in custom designs of Granite Based Positioning Systems.

There are a number of reasons granite offers advantages over polymer concrete structures:

Granite are the preferred structural material for applications like :