NUTEC highly experienced engineers integrate our products into positioning platforms relative to an industries application. These platforms could have up to 8 axis of motion, integrate laser systems, add pneumatic devices. These platforms are designed to be housed in a chassis and include the our MICROMATIC controller, highly organized cable routing, water features, and protective case with shielding.

These platforms come fully assembled, burn in and are tested. Designs can be altered to best suit your industries needs, taking our standard platforms and making them custom.

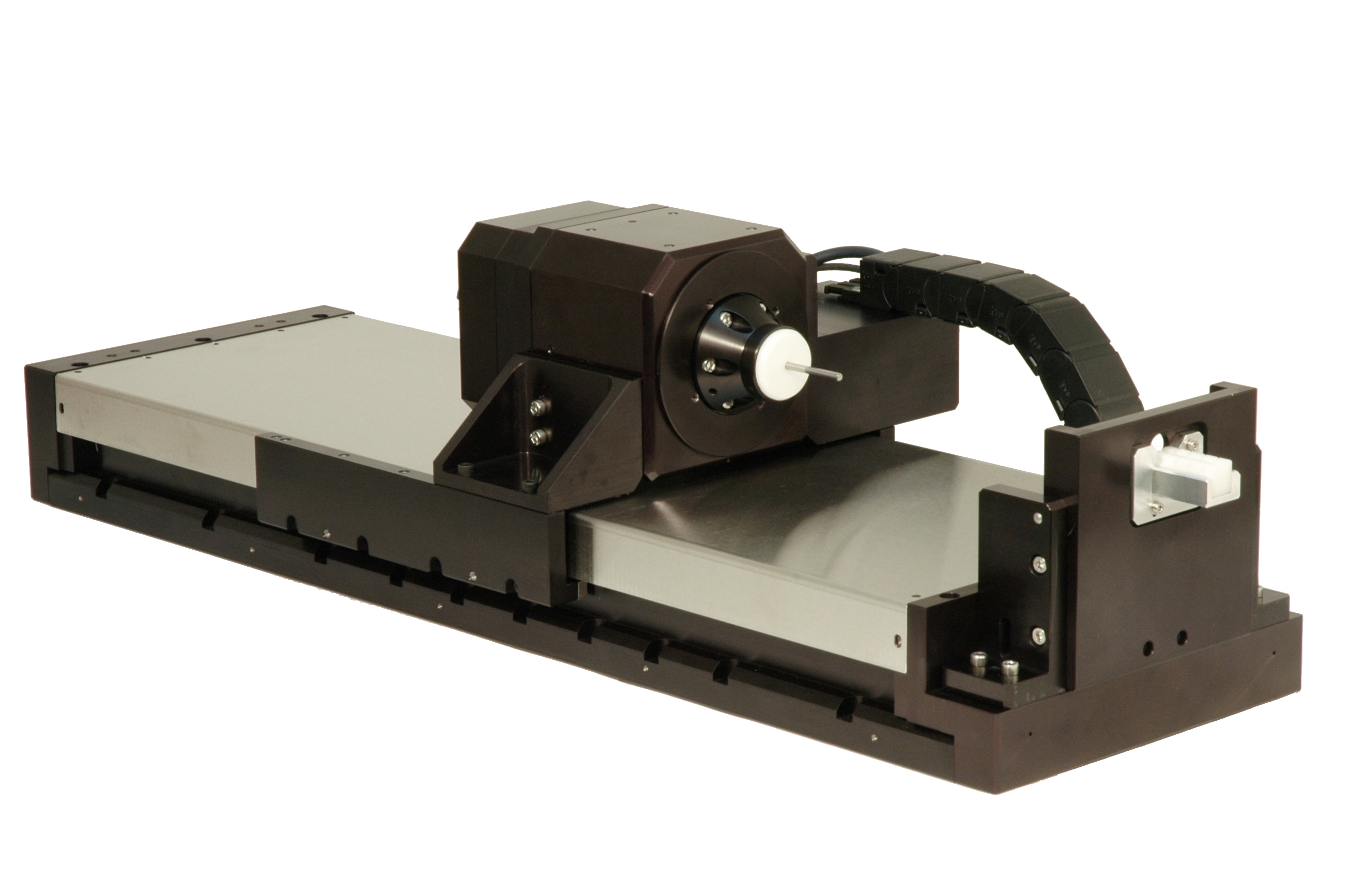

Next Gen LASERLATHE by NUTEC advances our already successful LASERLATHE with a low profile rotary minimizing mass yielding even higher axes acceleration for the highest possible throughput precision positioning and indexing of small diameter tubular and cylindrical components.

The LaserLathe advanced technology design creates a linear-rotary motion sub-system which expands the performance envelope for speed, precision and user friendliness. Typically, these attributes are highly desirable on laser machining systems for tube cutting operations, micro-drilling, helix/spiral cutting, surgical instrument production, implant machining, micro-welding and similar operations requiring highly precise and coordinated multi-axis linear-rotary motion.

Specific characteristics are these capabilities:

Simple design with minimal number of parts: easy end-user operation and lower cost of ownership. The end user benefits from expanded reliability and less down-time.

The CMS series tube and implant cutters are easy to use, have great flexibility for many different applications from long tube cutting to tiny implant machining and achieve unsurpassed productivity. A single enclosure small foot print includes a water system and mounting for a fiber laser. Its granite structure allows for permanent stability and includes vibration dampening support. Built for a long service life with easy accessibility for set-up and maintenance makes the CMS ideal manufacturing machine.

The CMS features NUTECs Advanced technology direct drive servo LaserLatheTM System. This system gives the CMS high burst acceleration for exceptional dynamic precision performance. Operating velocity reaches up to 50 mm/sec with a dynamic path bandwidth of less than 2 microns. Standard CMS has accuracy less than 3 microns, but a High Precision model has an accuracy up to 750 nanometers. All mechatronic motion systems are environmentally hardened IP54 for wet cutting capabilities. The CMS is equipped with an automatic hi-speed Tubing Re-feed Cycle increasing production times.

The CMS utilizes our industrial PC based PCNC nuFaceTM control system. It is a WindowsTM based GUI with extensive user-friendly features, functions, icons and warnings. The system uses G&M Code RS274 includes a monitor with softkeys or keyboard or both. nuFAceTM controls all features of the CMS including the front guiding system. This system has exceptional concentricity and co-axiality. A pneumatic collet module can be equipped for a wide range of collet types. The range of inserted tubing is 0.2 – 18 mm in diameter with a 32 mm option available.

Options

Laser and Beam Delivery

Water System for Wet Cutting

6-Axis Laser Micro Machining Center NUTEC introduces a unique multi-axis micro machining center for laser cutting small diameter parts in complex configurations. Typically used for surgical tools with a domed end, the system is capable of performing intricate path motion with great precision and optimized kinematics for smooth and uniform performance.

The optimized kinematics are created by a special architecture of all servo controlled translation axes to achieve constant velocity and cutting conditions throughout a wide range of operating conditions and enabling 24/7 operations. The granite structure based motion subsystem guarantees long term stability and precision.

The 300W High Stability SPI fiber laser is fully integrated and delivered by fine kerf optics and operates in CDRH Class 1 mode. The machine is equipped with an automated access door, light curtain for enhanced operator safety and a HEPA filtered exhaust system for gas and debris removal. An automated location gauging system allows fast loading by an operator or robot.

The machine operation is based on a CNC digital servo control with G&M-Code RS-274 capability and facilitated by a Windows™ based GUI nuFace with operator and engineering mode to continuously control and monitor all machine functions.

Typical applications include laser cutting bio-medical parts in the 1-8 mm diameter range with domed ends requiring spherical cuts, toothed designs, oblique contours and relief angles to create sharp edges.