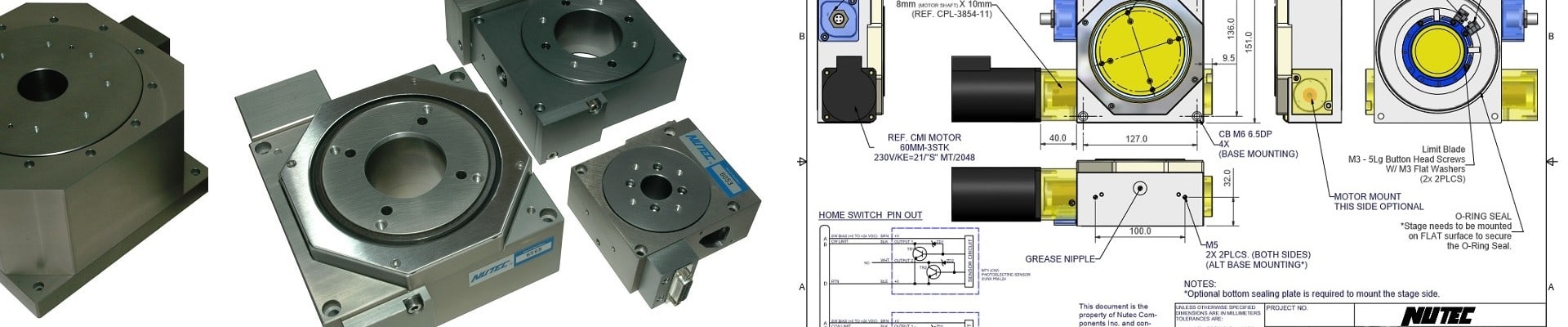

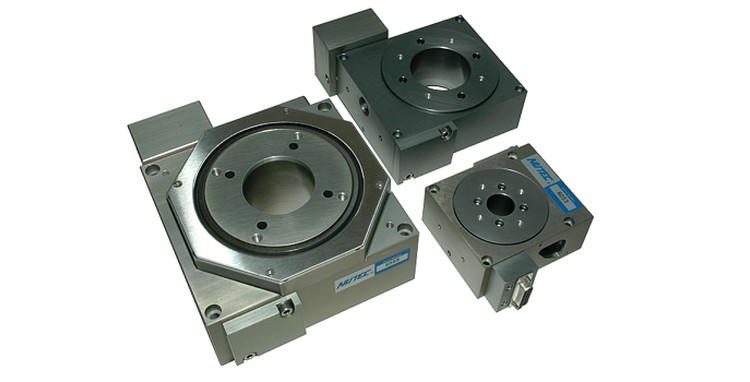

RT-Series of precision, gear-drive rotary positioning stages are ideal for today's high performance technology environment. They are found in virtually all industries where intermittent part indexing, skew adjustment or precise angular alignment is required and are well suited to holding position.

NUTEC’s RT-series, rotary stages offer high resolution and repeatability. These rotary stages are suitable for a wide number of uses ranging from lightweight positioning of optics to light duty machine tool applications and available with an optional sealed configuration.

All NUTEC rotary stages are machined from aluminum alloy finished with hard coat anodize providing a light and stiff stable structure. The design optimizes stage performance by utilizing a preloading thrust bearing in combination with the main hub bearing. This design approach offers excellent stability, reduced TIR, wobble and axial stability at low cost. A gear preload system insures zero backlash in the gear train. The RT-series have an optional cross roller bearings for high moment loading.

RT-series open frame, through bore, low profile rotary stages are available in a standard precision and high performance grade. The rotary top features a precision tolerance central aperture hub supported with two large diameter, preloaded precision bearings for increased stability.

The stage can be driven by either a servomotor or stepper motor, and the precision, pre-loaded, anti-backlash worm gear drive supports table rotation up to 45 rpm. RT series rotary tables can be mounted in any orientation, and attach readily to end-user equipment or directly to other NUTEC stages to form multi-axis positioning systems in an array of architectures.

RT-series rotary positioning stages are designed for precise motor driven rotary positioning and indexing. These tables are intended to function independently or in conjunction with other positioning components used in high precision and automation applications. The low-profile design minimizes stacking height in multi-axis configurations and enables RT-series stages to fit where other motorized devices cannot.

RT-series models are available with 67, 98 and 136 mm hub diameters with several resolution options, determined by encoder selected, to match speed and positioning requirements of your application.

| Capacities | RT-2 | RT-3 | RT-5 |

|---|---|---|---|

| Payload, Horizontal Mounting, Axial (kg) | 25 | 45 | 100 |

| Payload, Horizontal Mounting, Radial (kg) | 15 | 35 | 50 |

| Payload, Cross Roller XR, Horz Mtg, Radial (kg) | n/a | 50 | 100 |

| Motor Size | BSM 40 | BSM 40 or BSM 60 | BSM 60 |

| Velocity (RPM) 80:1 gear 3600 RPM drive motor | 45 | 45 | 45 |

| Max Output (N-m) | 11 | 14 | 17 |

| All RT-Series | |

|---|---|

| Travel | 360º Continuous |

| Drive Elements | Heat Treated; Steel Worm; Bronze Ring Gear |

| Drive Type | Precision Preloaded worm gear |

| Reduction Ratio | 80:1 |

| Accuracy | ± 2 arc minutes |

| Repeatability | ≤ 30 arc sec |

| Flatness of Rotation | ≤ 20 microns |

| Concentricity | ≤ 20 microns |