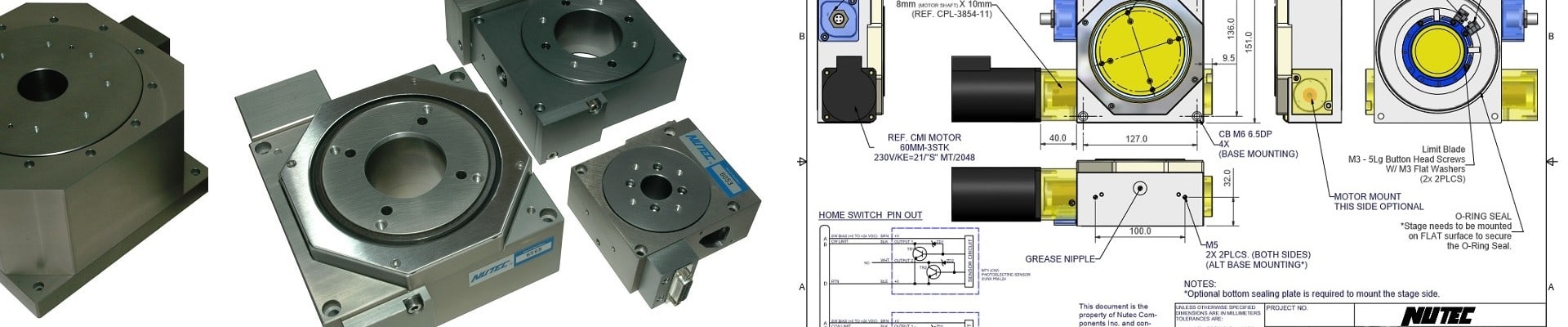

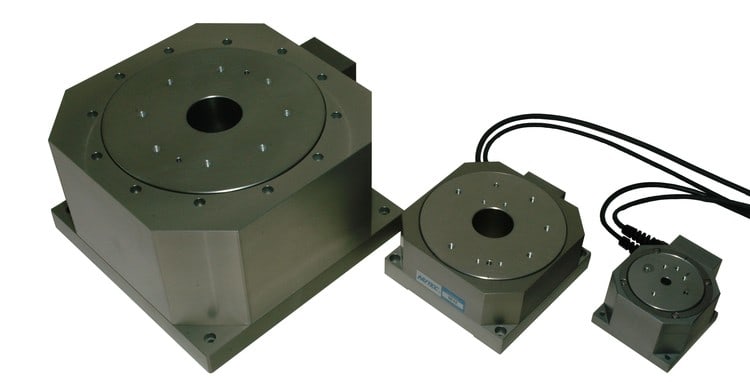

T-Max™ series of precision, direct-drive rotary servo positioning stages are ideal for today’s high performance technology environment. They are found in virtually all industries where intermittent part indexing, skew adjustment or precise angular alignment, continuous rotation and exact angular positioning is required.

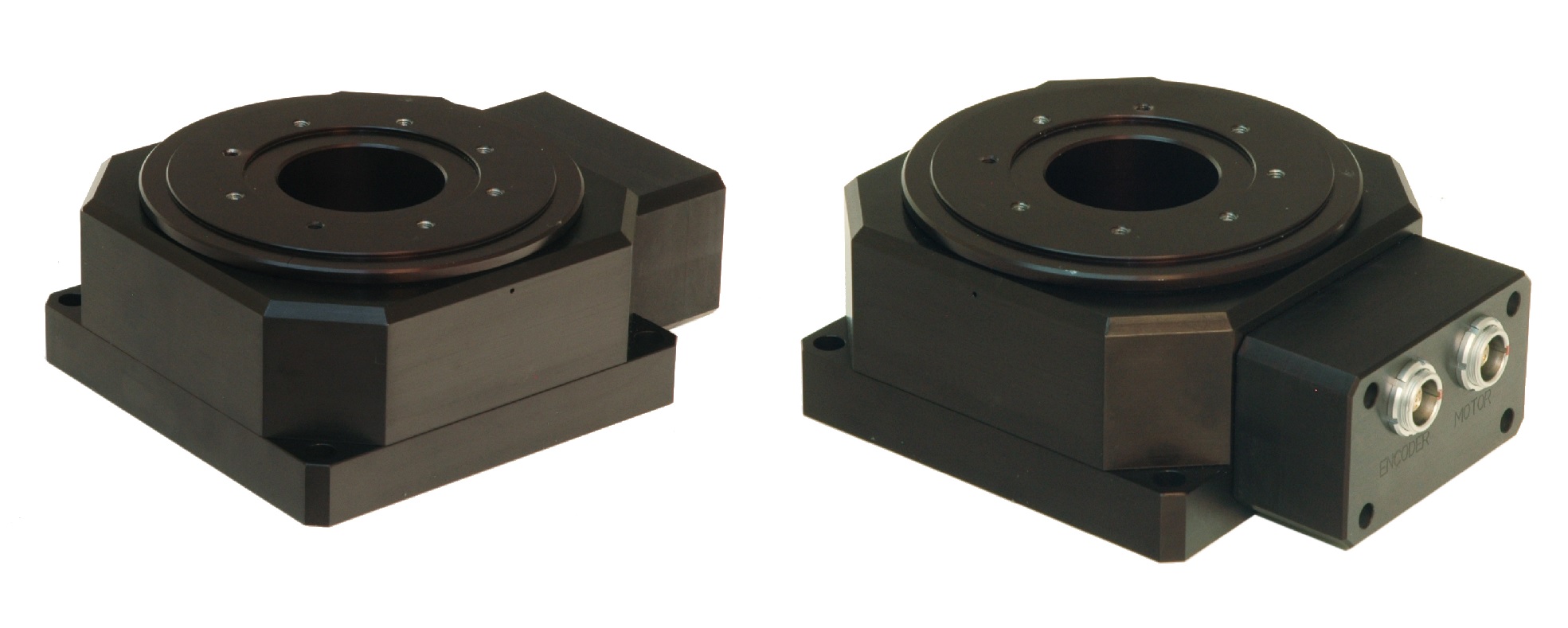

T-Max series of rotary stages provide smooth, low friction rotary motions over a large speed range with zero-backlash. These are key advantages in any application where excellent trajectory control is required. T-Max positioning stages operate with low vibration and superior flatness. These are attractive features in any precision application. Closed-loop rotary position control coupled with direct drive technology creates a robust rotating hub with low-hysteresis and remarkable angular resolution. The single piece rotating hub design affords rugged mechanical stability, integrity and increased precision under load. The double preloaded hub with a crossed-roller top bearing and duplex angular ball bearing at the bottom offers extreme stiffness and outstanding dynamic characteristics with low axial and radial run out even at maximum load. A top ball bearing configuration is available for low drag, damping and compliance as an option.

T-Max series rotary positioning stages are designed for precise motor driven rotary positioning and indexing. These rotary tables are intended to function independently or in conjunction with other positioning components used in high precision and automation applications. A low-profile design minimizes stacking height and Abbé error in multi-axis configurations and enables T-Max to fit where other motorized devices cannot.

T-Max models are available with 67, 98, 136 and 200 mm hub diameters in several resolution ranges configured to match speed and positioning requirements of your application.

A range of specialized configuration rotary positioning stages, based on the essential components of the T-Max stages are available to meet almost every application. Variants of these rotational stage products can be adapted for use in either clean rooms, vacuum chambers or sealed for operation in harsh environments while preserving all of their desirable high performance characteristics. Our Labyrinth seal protects T-Max from dust and spraying water, providing ingress protection rating IP53. These positioning stages can be factory equipped, tuned and tested with user supplied or custom or custom fabricated brackets gimbals and other tooling including a variety of work-holding collets, 3-jaw chucks and collet closing systems.

The newest addition to the T-Max series, this direct drive servo motor rotary stage offers a wider aperture (60 mm) and hub diameter (160 mm) than the rest of the series. This stage offers a high amount of continuous torque at 9.5 Nm. Designed for wet and dry environments the T-Max 6 has standard DB connectors with an optional waterproof LEMO Connectors.

Resolution is defined as the smallest angular value, which can be detected by the evaluating electronics as the hub turns relative to the base. Resolution is developed by the combined effect of the scale grating pitch, specified in lines per revolution (lpr) and an electronic multiplying factor, determined by the counting electronics.

Three configurations of electronic pulse counting systems are available in the T-Max product. All T-Max positioning stages share the same native analogue 1 Volt P-P encoder read head. This output is directly compatible with our MICROMATIC™series controllers and most other high-performance servo controllers.

Lower cost and performance controllers may require direct TTL encoder input signals. T-MAX system accomplishes this with an in-line analog to TTL pulse for signal conditioning. The In-line TTL conversion is achieved with a defined interpolation factor, 1x, 25x, or 100x. Contact factory for other interpolation factors.

| Capacities | T-Max 2 | T-Max 3 | T-Max 5 | T-Max6 |

|---|---|---|---|---|

| Std. Resolution (arc-sec) | 9 | 3.2 | 2.4 | 0.72 |

| HP Resolution (arc-sec) | 0.9 | 0.32 | 0.24 | call |

| Payload Axial (kg) | 10 | 18 | 25 | 35 |

| Payload Radial (kg) | 10 | 18 | 25 | 35 |

| Hub Diameter (mm) | 67 | 98 | 136 | 150 |

| Aperture Diameter (mm) | 9 | 8 | 38 | 60 |

| Continuous Torque (Nm) | 0.17 | 0.9 | 2.9 | 9.5 |

| Peak Torque (Nm) | 0.53 | 2.45 | 19.5 | 12.5 |

| Max Speed (RPM) | 850 | 300 | 1600 | 650 |

| HP Max Speed (RPM) | 420 | 150 | 500 | call |

| All T-Max | |

|---|---|

| Drive Elements | Non-contact servo torque motor |

| Reduction Ratio | N/A |

| Accuracy SP | 40 arc-second |

| Accuracy HP | 25 arc-second |

| Repeatability | ± 5 encoder counts |

| Flatness of Rotation | ± 6 microns |

| Concentricity | ≤ 4 microns |

| Wobble | ≤ 8 arc-seconds |