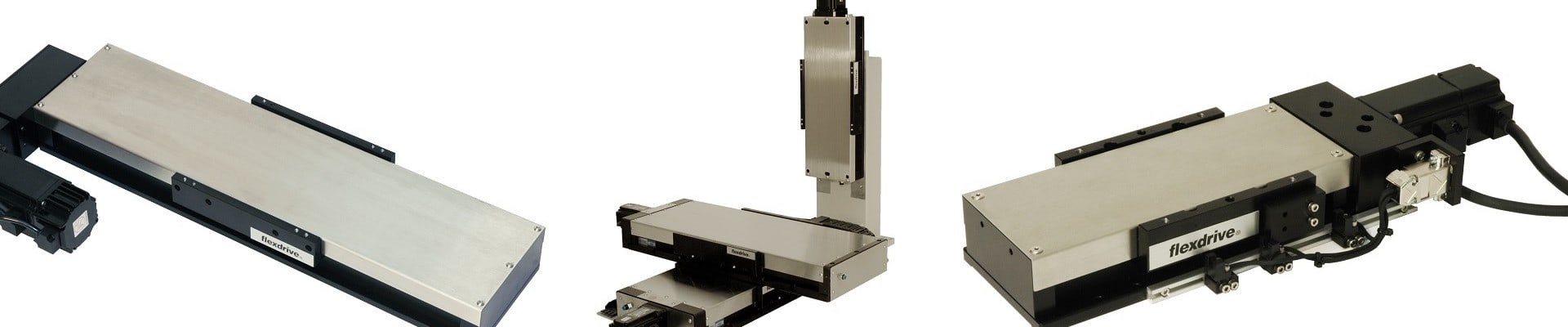

flexdrive™-4 Series linear positioning tables, has a small compact size and its modular design makes it an ideally suited translation module for a large number of applications requiring precision, reliability and ease of integration.

The flexdrive™-4 series is an expansion of the product line to a small compact size and the modular design makes it an ideally suited translation module for a larger number of applications requiring precision, reliability and ease of integration. Engineers, system integrators and designer prefer the flexdrive-4 for their superb performance, flexibility to match to the application and assured longevity.

The flexdrive-4 series is a very compact precision stage based on a monolithic high strength aluminum alloy with a 48 x 100 mm envelope and travel range from 50-450 mm. The payload capability is rated at 25 kg (55 lbs). The superb positioning performance is supported by square rails with recirculating low noise linear ball bearings and a precision ground ball screw drive.

The flexdrive-series positioning tables have been a very successful translator product for two decades and are recognized for their sustained positioning performance and longevity in many applications like laser machining systems, bio-medical, metrology, instrumentation and automation. The outstanding selection criteria are the reason why professionals prefer the clean, modern international metric design of the flexdrive-series stages by NUTEC. The designer’s preference for these modular concept positioners can be attributed to configurability for specific application requirements, the excellent specifications and the sustained performance coupled with longevity.

| Standard | Precision | ||||

|---|---|---|---|---|---|

| Travel Length | 50-450 mm | 50-450 mm | |||

| Accuracy | |||||

| Ball Screw Drive | ± 2 µm / 25mm | ± 1 µm / 25mm | |||

| Linear Encoder | N/A | 3 µm + 1 µm / 25mm | |||

| Servo & LIBEC | N/A | TBD | |||

| Ballscrew Drive System | |||||

| Ballscrew | Max. RPM | 3000 | 2000 | ||

| Repeatability, Typ | ± 1.5 µm | ± 1.2 µm | |||

| Repeatability, Max | ± 2.5 µm | ± 2.0 µm | |||

| Diameter ɸ | 12 mm | 12 mm | |||

| Ball Screw Lead | |||||

| Standard | 5 mm | 5 mm | |||

| Optional | 1 mm | 1 mm | |||

| Stroke | Flatness | Straightness | Flatness | Straightness | |

| 50 mm | 8 µm | 4 µm | 5 µm | 3 µm | |

| 100 mm | 10 µm | 4 µm | 7 µm | 4 µm | |

| 150 mm | 12 µm | 6 µm | 8 µm | 5 µm | |

| 200 mm | 12 µm | 8 µm | 10 µm | 5 µm | |

| 250 mm | 15 µm | 10 µm | 10 µm | 6 µm | |

| 300 mm | 20 µm | 12 µm | 10 µm | 6 µm | |

| 350 mm | 22 µm | 15 µm | 12 µm | 7 µm | |

| 400 mm | 25 µm | 15 µm | 15 µm | 8 µm | |

| 450 mm | 30 µm | 15 µm | 15 µm | 8 µm | |

| FD-4 SP | |

|---|---|

| Travel | 50 - 450 mm |

| Motor Interface | BSM 40 or BSM 60 |

| Maximum Acceleration | Payload Dependent |

| Max. Speed | |

| Standard | 1000 mm/s |

| Precision | 200 mm/s |

| Max. Axial Load | 300 N |

| Recommended Payload Limit | 25 kg / 55 lbs |

| Drive Efficiency | 80-90 % |

| Parasitic Torque Max. | .15 Nm |

| Drive Screw Max. | 3000 RPM |

| Construction | Aluminum Alloy Stainless Steel Cover |