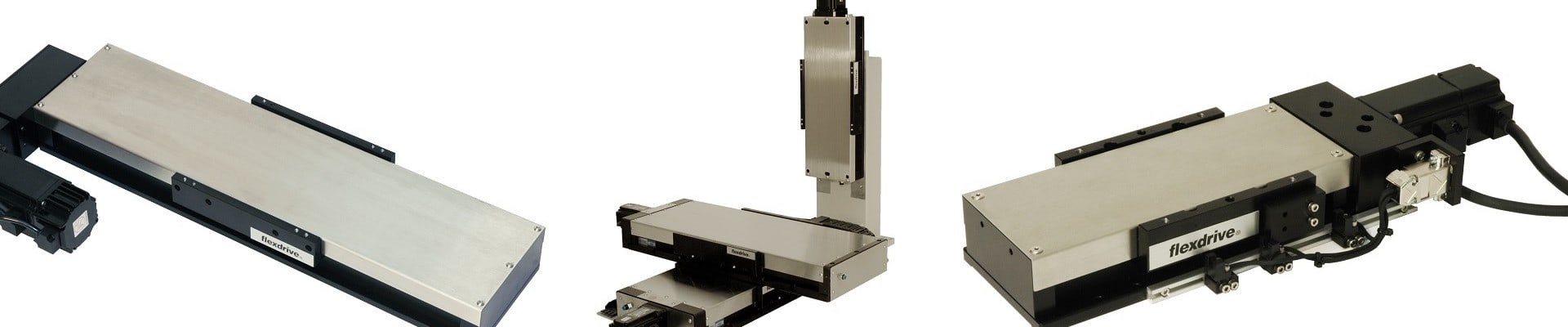

the flexdrive-8 series linear positioning tables, using a high-performance ball screw drive for positioning applications where high accuracy, longer travels, and high-load carrying capacities are required.

The flexdrive™-8 series is an expansion of the product line to a small compact size and the modular design makes it an ideally suited translation module for a larger number of applications requiring precision, reliability and ease of integration. Engineers, system integrators and designer prefer the flexdrive-8 for their superb performance, flexibility to match to the application and assured longevity.

The flexdrive series is a very compact precision stage based on a monolithic high strength aluminum alloy with a 74 x 227 mm envelope and travel range from 250-750 mm. The payload capability is rated at 70 kg/150 lbs. The superb positioning performance is supported by square rails with recirculating low noise linear ball bearings and a precision ground ballscrew drive.

This positioning stage is designed as a fine precision machine with selected high-performance components to achieve outstanding positioning performance with extended life expectancy. The stage base is fabricated from a specially selected hardened high-strength aluminum alloy slab, precision machined to extremely close tolerances. In addition, the saddle is equipped with a wear resistant hard-coat anodized protective finish.

The guide system features advanced technology multi-track linear bearings. The four integrally preloaded bearing carriages establish the proper stiffness and achieve constant support geometry for the saddle. This precise and rigid motion platform produces exceptional results in terms of accuracy and motion trajectory, even with high payload.

| FD-8250 | FD-8375 | FD-8500 | FD-8625 | FD-8750 | |

|---|---|---|---|---|---|

| Travel Length | 250 mm | 375 mm | 500 mm | 625 mm | 750 mm |

| Ball screw Diameter | 15 mm | 15 mm | 15 mm | 15 mm | 15 mm |

| Ball Screw Lead | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm |

| Trajectory Control | |||||

| Accuracy | |||||

| Rotary Encoder | ± 15 μm | ± 20 μm | ± 30 μm | ± 40 μm | ± 50 μm |

| Linear Encoder | ± 10 µm | ± 15 µm | ± 20 µm | ± 20 µm | ± 30 µm |

| Straightness/Flatness | ± 2.5 µm | ± 3.0 µm | ± 3.5 µm | ± 3.5 µm | ± 4.0 µm |

| Yaw/Pitch | 15 arc-sec | 15 arc-sec | 20 arc-sec | 30 arc-sec | 40 arc-sec |

| Repeatability, Typical | ± 1.5 µm | ± 1.5 µm | ± 1.5 µm | ± 1.5 µm | ± 1.5 µm |

| Repeatability, Max | ± 2.5 µm | ± 2.5 µm | ± 2.5 µm | ± 2.5 µm | ± 2.5 µm |

| 2 axis system | |||||

| Orthogonality | |||||

| Standard Grade | 10 arc-sec | 10 arc-sec | 15 arc-sec | 20 arc-sec | 20arc-sec |

| High Precision | 5 arc-sec | 5 arc-sec | 5 arc-sec | 5 arc-sec | 5 arc-sec |

| FD-8 SP | |

|---|---|

| Travel | 250 - 750 mm |

| Drive System | BSM 40 or BSM 60 |

| Maximum Acceleration | Payload Dependent |

| Max. Speed | Unladen 1000 mm/s |

| Maximum Axial Load | 300 N |

| Recommended Payload Limit | 100 kg / 150 lbs |

| Drive Efficiency | 80 - 90% |

| Parasitic Torque Max. | .15 Nm |

| Drive Screw Max. | 3000 RPM |

| Position Feedback | non-contacting digital Linear Encoder |

| Output | standard TTL - 4channel ; Optional 1Vpp with 20 µm grating pitch |

| Resolution | standard 50nm [ 0.050 µm ] Other resolution optional |

| Repeatability | 8x Resolution |