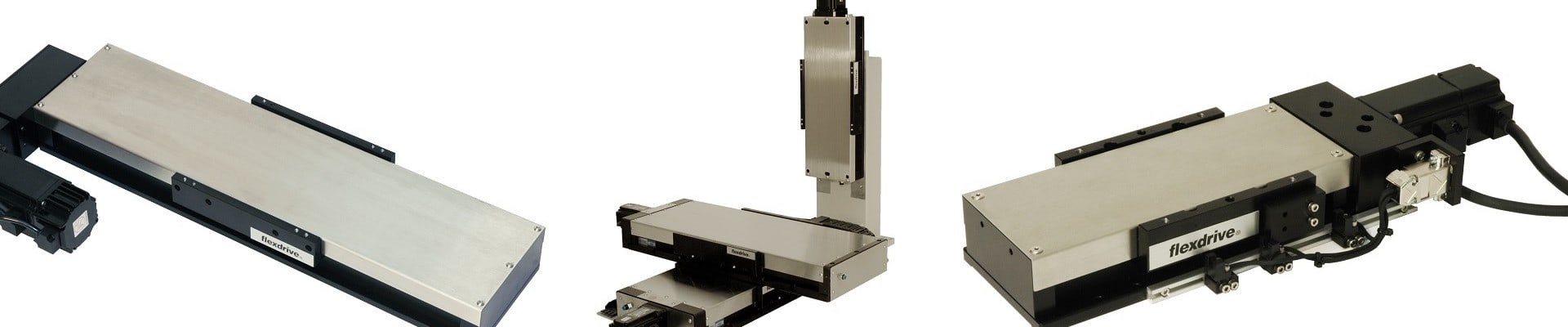

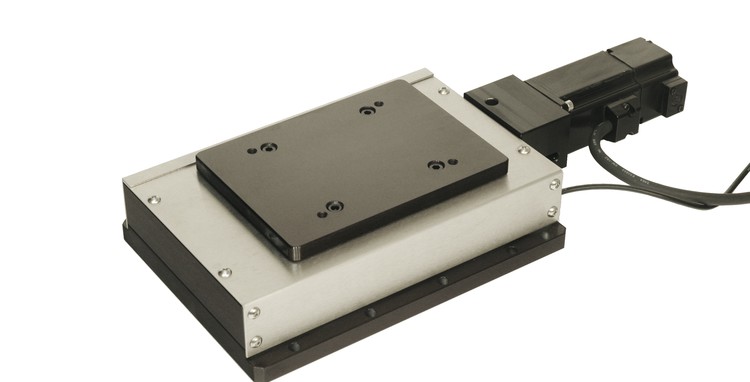

The Q-Max precision positioning stage series from NUTEC developed for maximum stiffness and high resolution. A short stroke translation stage capable of precise positioning in either vertical or horizontal orientations, while maintaining extremely tight trajectory control.

The Q-Max™ Precision Positioning Stage high stiffness positioning stage offers reliable linear positioning for trajectory and position critical applications. Guided by oversized needle bearing guides, featuring a constant bearing support geometry. The Q-MAX is driven to position via 1mm lead precision ground ballscrew. The drive system comes highly preloaded and offers low hysteresis without backdriving in vertical applications. This screw is suitable for drive by either a servo or stepper motor. The Q-Max includes digital limit/home sensors and a high-resolution linear encoder system. The Standard Q-Max is offered with an attractive gray hardcoat anodize finish or can be supplied in a clean room or vacuum preparation.

Wherever tight trajectory control is required, the Q-Max series of positioning stages meet the most demanding positioning requirements. Optical Metrology in semiconductor, flat panel and microelectronics are prime applications. Use for precision dispense and liquid extrusion dispensing in the microelectronic wafer fabrication industry. In the photonic instrument field, wherever position adjustment is critical for example the focus adjustment of fast, high numerical aperture, high magnification imaging systems, Q-Max is the right choice. Q-Max is used by many brand name automatic inspection and machine vision OEM’s, Q-Max has the precision required for a range of positioning tasks including holographic inspection and high magnification imaging inspection and testing. It can be used extremely well for vertical Z-axis applications with overhanging payloads that create an offset moment loading. It is equally well suited for horizontal applications requiring high stability, low trajectory error and high resolution for long term reliable positioning.

| QMX-25 | QMX-50 | QMX-100 | |

|---|---|---|---|

| Travel Length | 25 mm | 50 mm | 100 mm |

| Trajectory Control | |||

| Accuracy | |||

| Standard SP | ± 2.0 µm | ± 3.0 µm | ± 4.0 µm |

| High Precision HP | ± 0.5 µm | ± 1.0 µm | ± 1.5 µm |

| Straightness/Flatness | |||

| Standard SP | ± 1.0 µm | ± 2.0 µm | ± 3.0 µm |

| High Precision HP | ±0.5µm | ±0.5µm | ±0.5µm |

| Yaw/Pitch/Roll | |||

| Standard SP | 5 arc-sec | 7.5 arc-sec | 9 arc-sec |

| High Precision HP | 4 arc-sec | 5 arc-sec | 6 arc-sec |

| Extra High Precision XHP* | 3 arc-sec | 4 arc-sec | 5 arc-sec |

| Resolution | |||

| Linear Encoder | Standard | 50nm | |

| Optional | consult factory | ||

| Rotary Encoder | @1 mm lead | 100nm | |

| @5 mm lead | 50.8nm | ||

| 2 axis system | |||

| Orthogonality | |||

| Standard SP | 20 arc-sec | 20 arc-sec | 20 arc-sec |

| High Precision HP | 10 arc-sec | 10 arc-sec | 10 arc-sec |

| Extra High Precision XHP | 5 arc-sec | 5 arc-sec | 5 arc-sec |

| QMX–SP | ||

|---|---|---|

| Travel Length | 25, 50 and 100 mm | |

| Drive System | Ballscrew BSM 40 | |

| Ballscrew Pitch | 1 mm | |

| Maximum Acceleration | Payload Dependent | |

| Maximum Speed | Unladen 30 mm/s | |

| Recommended Payload limit Q-Max 25 | 15 kg | |

| Recommended Payload limit Q-Max 50 | 30 kg | |

| Recommended Payload limit Q-Max 100 | 35 kg | |

| Feedback | Non-Contact Linear Encoder System | |

| Repeatability | ≤ 100 nm |