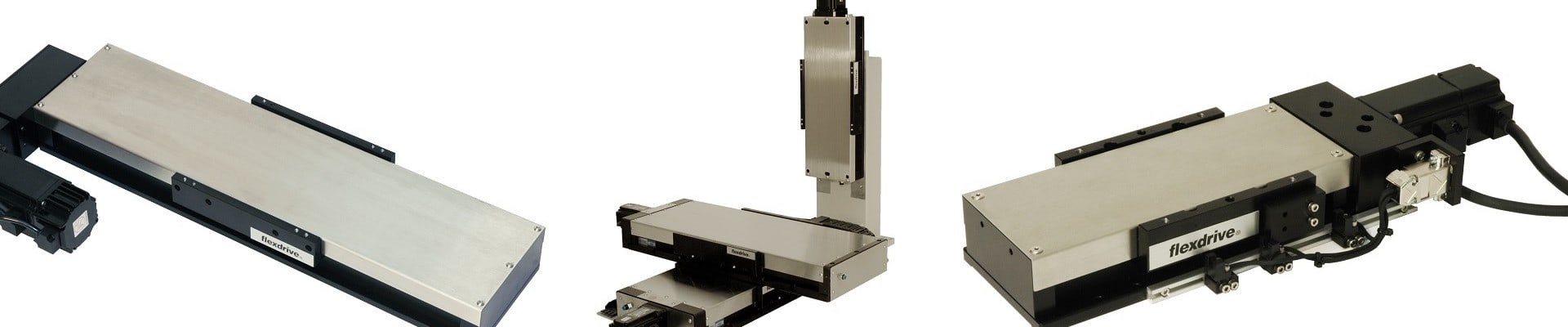

Elevator Stage ES-200 is designed for vertical Z-axis applications requiring extremely fine incremental up-down motions. The ES-200 offers high resolution, high repeatability and high mechanical stability. The dual column guide and the patented single plane wedge drive achieve exceptional narrow bandwidth trajectory.

ES-200 Stages designed with high density cross-roller guides for both the vertical guide and the wedge drive to assure maximum stability within the smallest footprint. Dual-column vertical X-roller guides offer high stiffness with appropriate levels of preload create a unit with very low hysteresis and considerable loading capacity. The design is fully metric and modular in style. The wedge drive mechanism is separate from the elevator mechanism permitting various combinations of wedge angle, rotary or linear motor drives, and linear/rotary encoder options. This modular adaptable design allows the elevator stage to be configured to match the application exactly.

Primary applications of the elevator stage include: vertical positioning in optical systems to achieve perfect focal plane alignment, video systems, video metrology, laser work, inspection, semiconductor testing and manufacturing processes, and similar applications where precise and repeatable vertical motion is essential. The modularity of the design permits the ES-200 Stage to be easily integrated into existing stage systems, including open frame metrology stages, or to be used as a standalone stage. The stability of the Z-axis design also permits this stage to be a carrier stage for X/Y and Theta translation and positioning systems. The stage is easily interfaced, both mechanically and electrically, with BSM60 motor face connection or other motor interfaces.

| Model | ES-200-10 | ES-200-16 |

|---|---|---|

| Travel Length | 10 mm | 16 mm |

| Trajectory Control | ||

| Accuracy | ||

| Standard (SP) | ± 1 µm F.T. | ± 1 µm F.T. |

| High Precision (HP) | ± 0.5 µm F.T. | ± 0.5 µm F.T. |

| Straightness/Flatness | ||

| Standard (SP) | ± 1 µm F.T. | ± 1 µm F.T. |

| High Precision (HP) | ± 0.5 µm F.T. | ± 0.5 µm F.T. |

| Integrated Rotary Stage Option | ||

| Resolution | 0.9 arc sec 9.0 arc sec |

0.9 arc sec 9.0 arc sec |

| ES-200-SP | |

|---|---|

| Drive System | BSM60 Servo Motor |

| Wedge | 2:1 Reduction Ratio |

| Maximum Acceleration | Payload Dependent |

| Max Speed | Unladen 10 mm/s |

| Recommended Payload Limit | 15 kg |

| Feedback | Non-Contact Linear Encoder |

| Resolution | 50 nm |

| Repeatability | < 1 μm |

| Construction | Aluminum Alloy Body, Hard Coat Anodize |